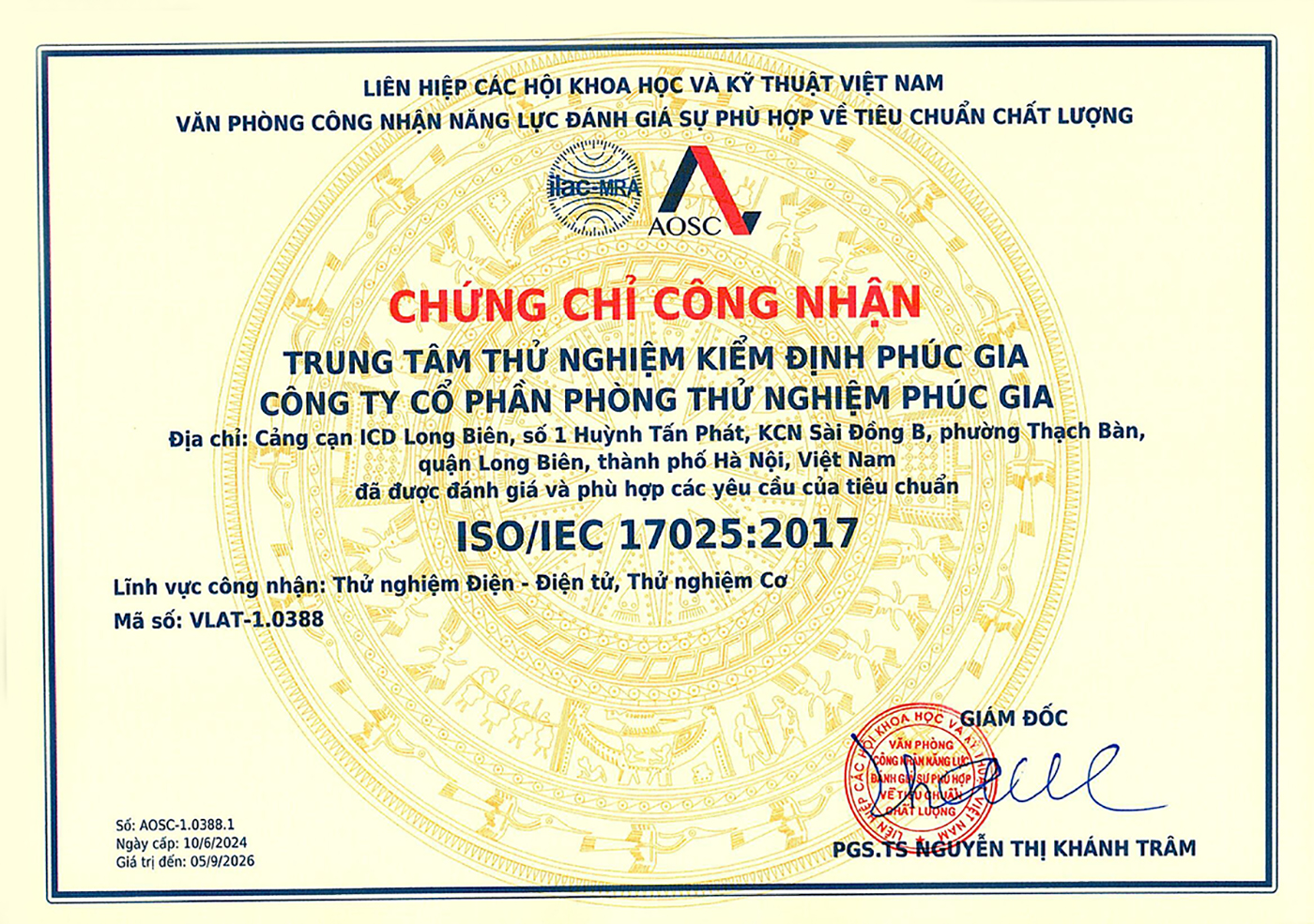

See more: Capacity Profile Of Phuc Gia Laboratory Corporation

What is Electromagnetic Compatibility (EMC)?

Electromagnetic Compatibility (EMC) is the ability of electrical equipment to function normally in an electromagnetic environment (the current environment in which people live and work) without causing electromagnetic interference to any other electrical equipment or systems. For example, when a light bulb is lit, a hairdryer is running, or a handheld drill is operating, those devices themselves must have the ability to resist external interference while simultaneously ensuring they do not cause electromagnetic interference to other electrical devices.

When an electrical or electronic device operates normally, it emits electromagnetic radiation (emissions). In other words, when electrical equipment operates normally, it inherently generates electromagnetic interference waves characterized by specific wavelengths and interference intensity. The higher the radiation intensity, the more it affects the normal operation of surrounding devices and the environment. An EMC-compliant electrical device must ensure that it works normally when other signal sources are active, and at the same time, it must not generate electromagnetic interference that exceeds allowable standards relative to the normal operation of other equipment.

EMC Testing Process

EMC testing according to QCVN 09:2012 Amendment 1:2018 is the process of evaluating the level of electromagnetic radiation emissions for the following devices:

-

Electric motor-operated handheld drills

-

Self-ballasted lamps

-

Vacuum cleaners

-

Washing machines

-

Refrigerators and freezers

-

Air conditioners

-

Hairdryers

-

Blenders, meat grinders, fruit juicers, and egg beaters

-

Microwave ovens (including combination types)

-

Electric stoves (including induction cooktops)

EMC Testing Parameters:

Electrical and electronic devices are tested for the following parameters in the field of EMC:

-

Conducted Emission Measurement (Terminal Voltage): Measures the interference at the power plug of the device when connected to the power source; the unit of conducted interference at the power terminal is dB (uV).

-

Disturbance Power Measurement: Measures the intensity of interference at the terminals and along the power cord of the device; the unit of disturbance power is dB/pW.

Equipment in EMC Testing:

-

Shielded Room (Isolation Chamber): An enclosed workspace with walls made of panels designed to block external electromagnetic signals from entering and internal signals from escaping, creating a completely isolated workspace.

-

Measuring Receiver: A device that records the electromagnetic interference signals of the equipment.

-

Line Impedance Stabilization Network (LISN): A power source provider for the test sample that eliminates all noise factors from the external environment.

-

Absorbing Clamp: A device used to pick up interference signals on the power cord of the equipment and transmit them to the measuring receiver.

-

Receiving Antenna: A device used to capture interference signals emitted from the equipment during operation.

The EMC testing process is conducted inside the isolated shielded room. The Equipment Under Test (EUT) is operated normally, followed by the recording of measurement signals through conducted interference and disturbance power parameters.

RELATED POSTS:

For more details, please contact us at:

PHUC GIA LABORATORY CORPORATION

PHUC GIA CERTIFICATION CENTER

PHUC GIA INSPECTION TESTING CENTER

Address: ICD Long Bien, No. 01 Huynh Tan Phat, Sai Dong B Industrial Park, Long Bien Ward, Hanoi City, Vietnam.

Hotline: 0981 996 996/ 0982 996 696/ 024 7779 6696

E-mail: lab@phucgia.com.vn/cert@phucgia.com.vn/info@phucgia.com.vn

Website: phucgia.com.vn

Working time: Monday to Friday 8:00 – 18:30; Saturday 8:00 – 12:00

![QUOTATION – Testing and Other Certification Services [2026]](https://phucgia.com.vn/wp-content/uploads/2017/03/bao-gia-thu-nghiem-chung-nhan.png)