Electrical wires and cables are indispensable devices in electrical systems, used in households, offices, and industrial construction. These devices reliably conduct electricity and connect equipment. The diversity in wire types, cross-sections, power ratings, and operating environments requires these products to strictly comply with the legal regulations for electrical wires and cables in Vietnam to ensure safety for users and connected equipment.

See more: Capacity Profile Of Phuc Gia Laboratory Corporation

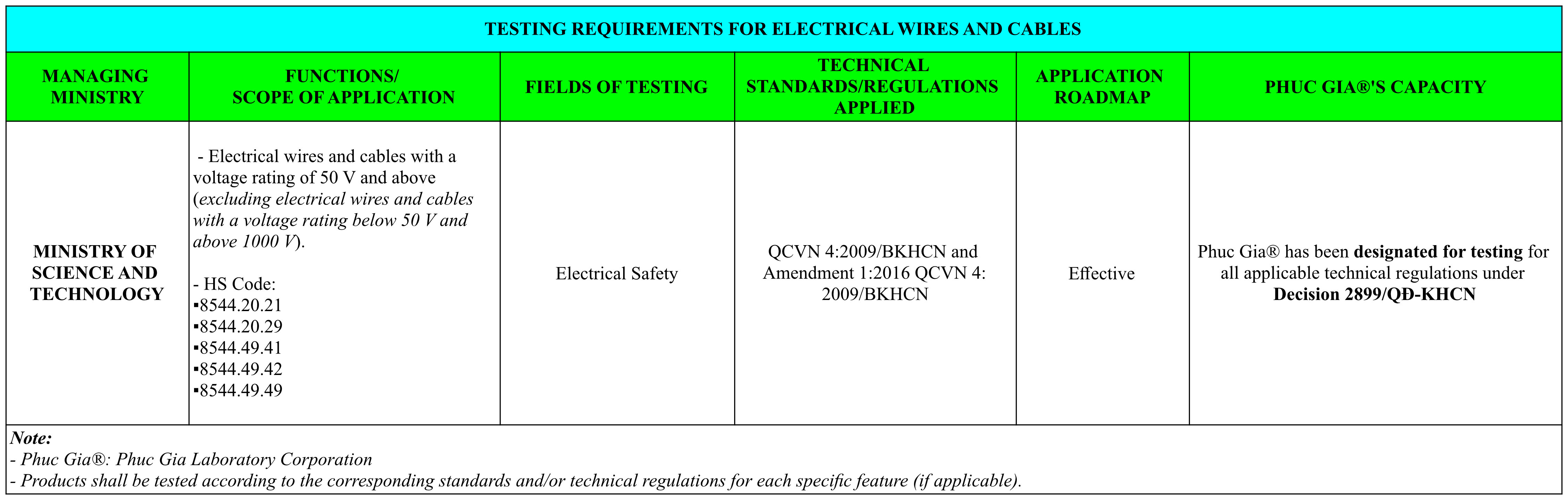

Table 1: Testing Requirements for Electrical Wires and Cables in Vietnam

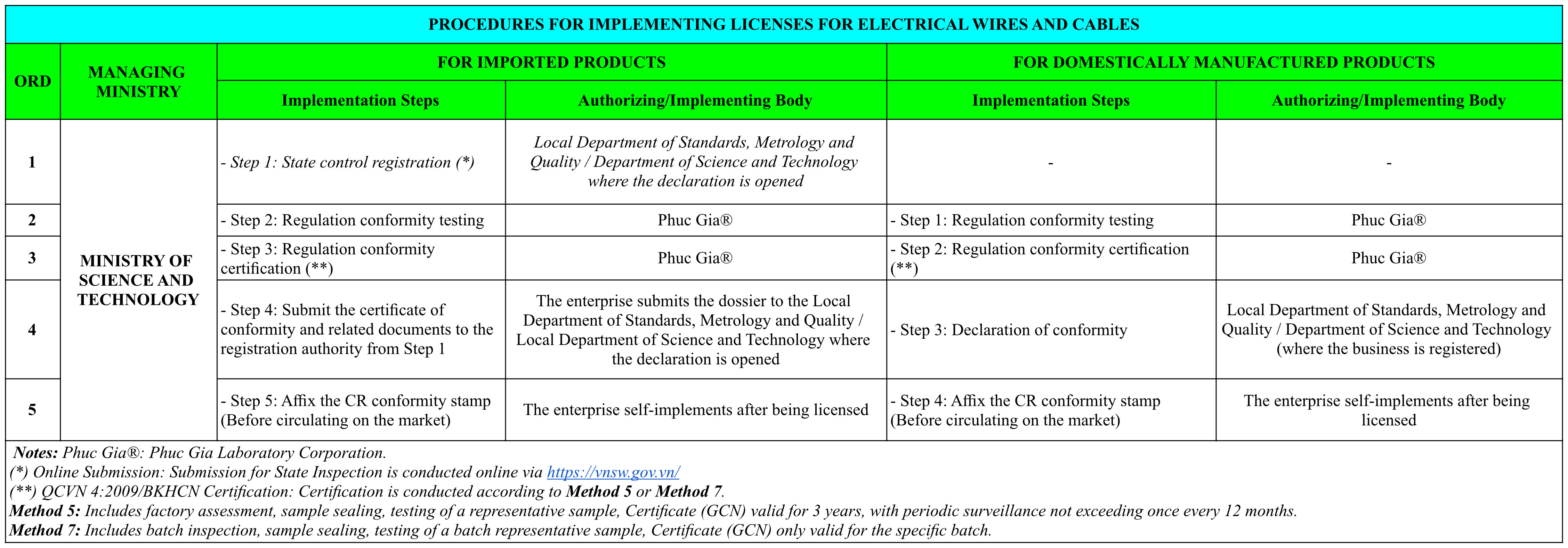

Table 2: Procedures for Implementing Licenses for Electrical Wires and Cables

I. What are Electrical Wires and Cables?

Electrical wires and cables are devices used to conduct electricity and transmit signals in civil, office, and industrial electrical systems. These devices help transmit and distribute electrical energy, supporting safe and stable equipment operation. However, wires and cables have significant differences in structure, load capacity, and usage scope. Clearly understanding each type not only helps select the correct product for each application but also contributes to ensuring electrical safety and compliance with technical requirements during design, construction, or inspection.

Electrical Wire: A conductor consisting of a metal core for transmitting electricity and an outer insulating sheath. Due to its flexibility and ease of installation, electrical wire is commonly used in civil electrical systems such as concealed wiring, connecting sockets/switches, lighting systems, and powering small- to medium-capacity household appliances. Beyond residences, wires are also used in electronic devices, vehicles, and various applications requiring moderate signal or power transmission.

Electrical Cable: Has a more complex structure, typically consisting of multiple conductive cores encased in multiple layers of insulation and mechanical protection. Due to its high load capacity, durability, and ability to operate in harsh environments, electrical cable is widely applied in industrial and large-scale projects. Typical applications include: transmitting electrical energy from substations to residential areas or factories; underground urban electrical systems; supplying power to high-capacity motors; and projects requiring high standards for fire safety through fire-resistant cables.

II. Legal Regulations for Electrical Wires and Cables in Vietnam

1. Procedures for Implementing Licenses for Electrical Wires and Cables

a) For Imported Electrical Wires and Cables

| MANAGING MINISTRY | IMPORTED ELECTRICAL WIRES AND CABLES | |

| Implementing Steps | Authorizing/Implementing Body | |

| Ministry of Science and Technology | Step 1: State control registration (*) | Local Department of Standards, Metrology and Quality / Department of Science and Technology where the declaration is opened |

| Step 2: Regulation conformity testing | Phuc Gia® | |

| Step 3: Regulation conformity certification (**) | Phuc Gia® | |

| Step 4: Submit the certificate of conformity and related documents to the registration authority from Step 1 | The enterprise submits the dossier to the Local Department of Standards, Metrology and Quality / Local Department of Science and Technology where the declaration is opened | |

| Step 5: Affix the CR conformity stamp (Before circulating on the market) |

The enterprise self-implements after being licensed | |

Notes: Phuc Gia®: Phuc Gia Laboratory Corporation.

(*) Online Submission: Submission for State Inspection is conducted online via https://vnsw.gov.vn/

(**) QCVN 4:2009/BKHCN Certification: Certification is conducted according to Method 5 or Method 7.

Method 5: Includes factory assessment, sample sealing, testing of a representative sample, Certificate (GCN) valid for 3 years, with periodic surveillance not exceeding once every 12 months.

Method 7: Includes batch inspection, sample sealing, testing of a batch representative sample, Certificate (GCN) only valid for the specific batch.

b) For Domestically Manufactured Electrical Wires and Cables

| MANAGING MINISTRY | DOMESTICALLY MANUFACTURED ELECTRICAL WIRES AND CABLES | |

| Implementing Steps | Authorizing/Implementing Body | |

| Ministry of Science and Technology | Step 1: Regulation conformity testing | Phuc Gia® |

| Step 2: Regulation conformity certification (*) | Phuc Gia® | |

| Step 3: Declaration of conformity | Local Department of Standards, Metrology and Quality / Department of Science and Technology (where the business is registered) | |

| Step 4: Affix the CR conformity stamp (Before circulating on the market) |

The enterprise self-implements after being licensed | |

Notes: Phuc Gia®: Phuc Gia Laboratory Corporation.

(*) QCVN 4:2009/BKHCN Certification: Certification is conducted according to Method 5 or Method 7.

Method 5: Includes factory assessment, sample sealing, testing of a representative sample, Certificate (GCN) valid for 3 years, with periodic surveillance not exceeding once every 12 months.

Method 7: Includes batch inspection, sample sealing, testing of a batch representative sample, Certificate (GCN) only valid for the specific batch.

2. Legal Regulation Documents

| Ministry of Science and Technology | |

| Legal Regulation Documents | – Decision No. 2711/QĐ-BKHCN (Issued 30/12/2022) of the Ministry of Science and Technology (MOST), announcing the list of Group 2 products and goods [subject to mandatory quality inspection].

– Circular No. 01/2022/TT-BKHCN (Issued 16/02/2022) of the Minister of Science and Technology, amending Circular No. 07/2018/TT-BKHCN and Circular No. 08/2019/TT-BKHCN. – Circular No. 02/2017/TT-BKHCN (31/03/2017) of the Ministry of Science and Technology, promulgating regulations on standard conformity declaration, regulation conformity declaration, and conformity assessment methods against technical standards and regulations. – Circular No. 21/2016/TT-BKHCN (15/12/2016) of the Ministry of Science and Technology, promulgating Amendment 1:2016 to QCVN 4:2009/BKHCN (National Technical Regulation on Safety for Electrical and Electronic Equipment). – Circular No. 28/2012/TT-BKHCN (30/09/2009) of the Ministry of Science and Technology, promulgating regulations on standard conformity declaration, regulation conformity declaration, and conformity assessment methods against technical standards and regulations. – Circular No. 21/2009/TT-BKHCN (30/09/2009) of the Ministry of Science and Technology, promulgating and implementing the “National Technical Regulation on Safety for Electrical and Electronic Equipment” (QCVN 4:2009/BKHCN). |

3. Types of Electrical Wires and Cables within the Scope of Application

| Ministry of Science and Technology | |

| Types of Electrical Wires and Cables within the Scope of Application | According to Decision No. 2711/QĐ-BKHCN, low-voltage electrical wires and cables (excluding electrical wires and cables with a voltage rating below 50 V and above 1000 V) must comply with the electrical safety testing requirements under QCVN 4:2009/BKHCN and Amendment 1:2016 QCVN 4:2009/BKHCN.

This requirement applies when the product falls under 1 of the following 5 HS codes:

|

4. Currently Effective Regulations/Standards

| Ministry of Science and Technology | |

| Currently Effective Regulations/Standards | The National Technical Regulation QCVN 4:2009/BKHCN/SĐ01:2016 on Safety for Electrical and Electronic Equipment – Amendment 1:2016 stipulates that electrical wires and cables must comply with the following technical standards:

|

5. Important Notes in Importation, Manufacturing, and Business Policies under the Legal Regulations for Electrical Wires and Cables in Vietnam

| Ministry of Science and Technology | |

| Important Notes | – Testing and Certification Authority: Testing and certification must be conducted by a testing and certification organization that is designated, registered, or recognized by the Ministry of Science and Technology (MOST).

– Post-Certification Declaration: Domestic manufacturers and importers of electrical wires and cables, after obtaining conformity certification, must register their Declaration of Conformity at the local Sub-Department of Standards, Metrology, and Quality (Chi cục Tiêu chuẩn Đo lường Chất lượng) where the enterprise is registered, before circulating the product in the market. – Certification Method 5 (System Assessment): The Certificate of Conformity is valid for no more than 3 years. The enterprise must retain records for no less than 10 years from the date the final product of the registered type/model is released. – Certification Method 7 (Batch Assessment): The Certificate of Conformity is valid only for the specific batch/lot of products. – Notes on Sample Collection (Typical Sample):

– Sample Management: For both Method 5 and Method 7, two sets of samples are collected: one set is sent to the testing laboratory, and one set is retained by the client for comparison and retesting if the client disagrees with the initial results. – Labeling Requirements on Wires and Cables:

– Scope Exclusion & Declaration: Electrical wires and cables with a voltage rating below 50 V and above 1000 V are excluded from the scope of QCVN 4:2009/BKHCN and Amendment 1:2016. Enterprises manufacturing or importing wires/cables with a voltage rating below 50 V must declare the standard applied to the product. Labeling on these wires/cables must clearly state the corresponding voltage rating. |

III. PHUC GIA LABORATORY CORPORATION: COMPREHENSIVE SERVICES FOR ELECTRICAL WIRES AND CABLES

| ORD | PHUC GIA® CAPABILITIES | MINISTRY OF SCIENCE AND TECHNOLOGY |

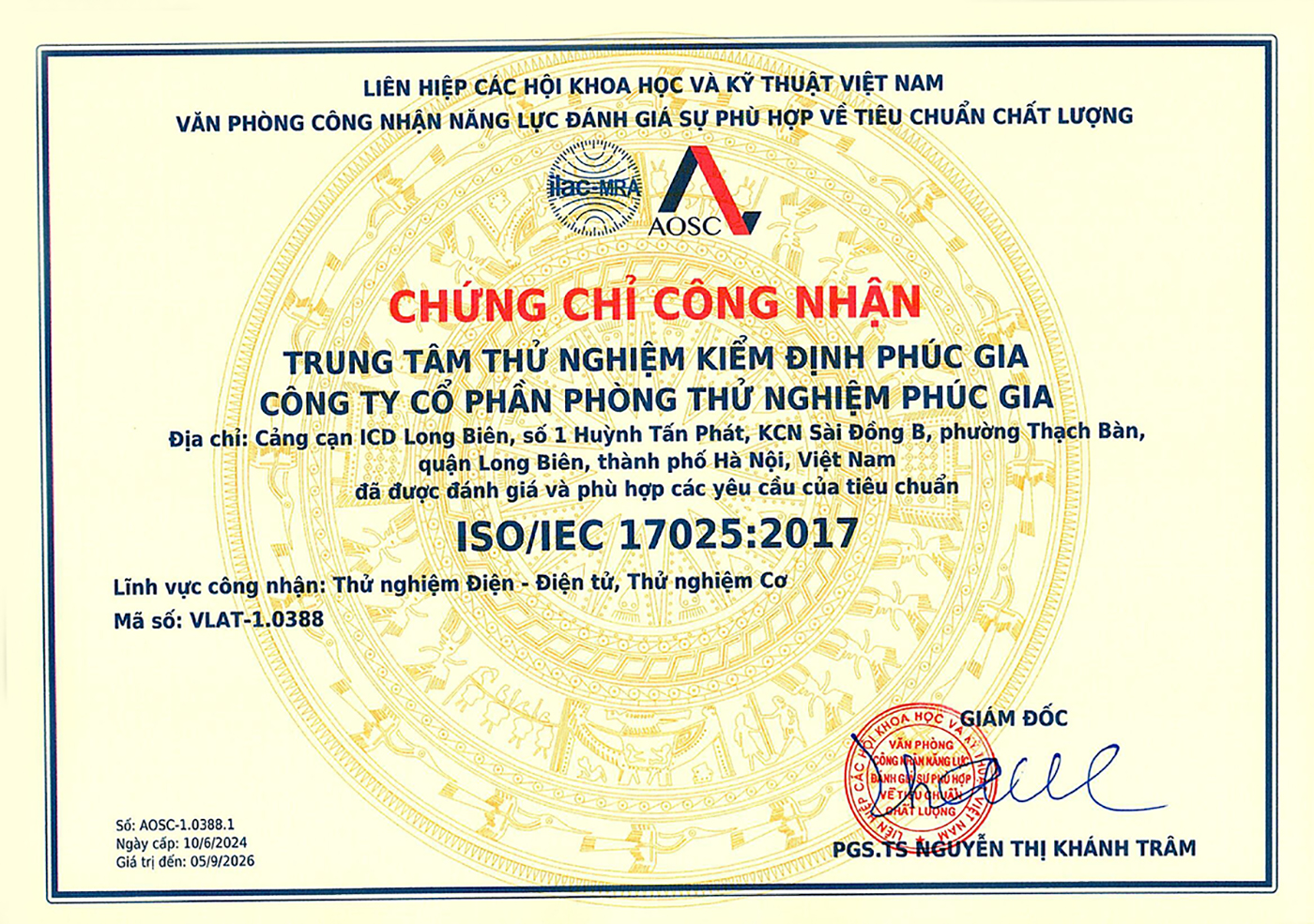

| 1 | Testing Capabilities (Certification/ Designation) |

Phuc Gia® has been designated for testing and certification of electrical safety and remains effective/valid. (Detail) |

| 2 | Quotation and Duration for Tests | The official listed quotation is available here. |

| 3 | Support | – Consultancy on product quality improvement;

– Free 24/7 consultation service; – Consultancy on product quality improvement. |

| 4 | Contact for Services | For assistance with testing/certification, please contact:

Address: ICD Long Bien, No. 01 Huynh Tan Phat, Sai Dong B Industrial Park, Long Bien Ward, Hanoi |

RELATED POSTS:

- List of Conformity Assessment Activities for Electrical Wires and Cables

- Guidance on Electrical Safety Testing for Electrical Wires and Cables according to QCVN 4:2009/BKHCN

- Conformity Certification for Hand Dryers

- Comprehensive Legal Regulations for Hair Dryers

- Comprehensive Legal Regulations for Water Dispensers

- Comprehensive Legal Regulations for Storage Water Heaters

- Comprehensive Legal Regulations for Instant Water Heaters

For more details, please contact us at:

PHUC GIA LABORATORY CORPORATION

PHUC GIA CERTIFICATION CENTER

PHUC GIA INSPECTION TESTING CENTER

Address: ICD Long Bien, No. 01 Huynh Tan Phat, Sai Dong B Industrial Park, Long Bien Ward, Hanoi City, Vietnam.

Hotline: 0981 996 996/ 0982 996 696/ 024 7779 6696

E-mail: lab@phucgia.com.vn/cert@phucgia.com.vn/info@phucgia.com.vn

Website: phucgia.com.vn

Working time: Monday to Friday 8:00 – 18:30; Saturday 8:00 – 12:00

![QUOTATION – Testing and Other Certification Services [2025]](https://phucgia.com.vn/wp-content/uploads/2025/01/quotation.png)