Phuc Gia® is an organization that provides consumer information on the components and operating principle of water heaters, aiming to help you gain more experience in product selection and know how to troubleshoot when unexpected situations occur during the use of a water heater!

See more: Capacity Profile Of Phuc Gia Laboratory Corporation

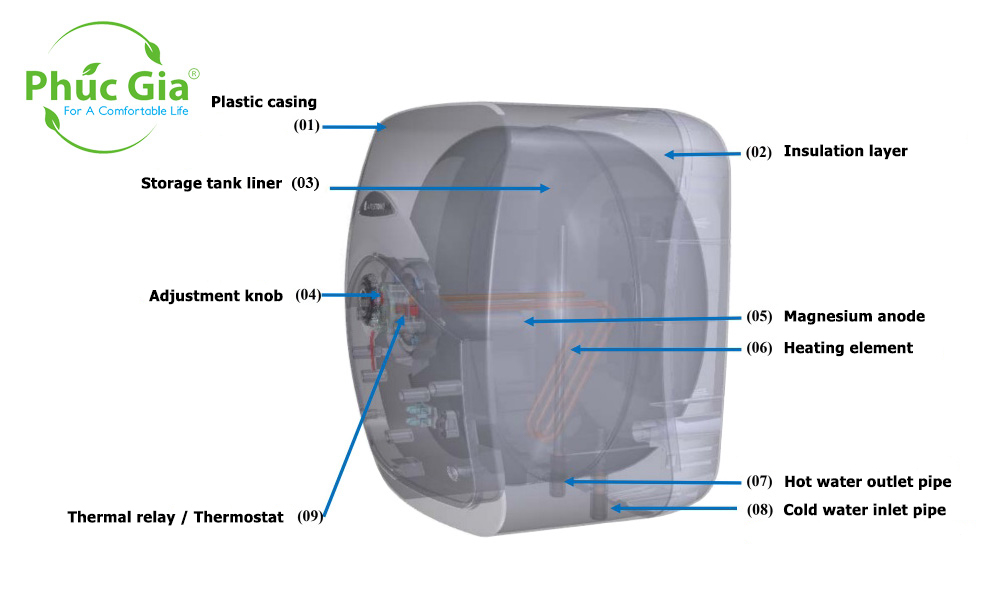

I) The Structure of the Water Heater Includes 10 Main Components

1. The water heater tank lining has 2 types:

- Enamel-coated tank lining for corrosion protection: Currently, all manufacturers of Water Heaters produce this type. The tank core is made from specialized steel plates for enameling. Next, they are coated with an enamel layer and then placed in a furnace at a temperature of approximately 800ºC. At this temperature, the glass enamel begins to melt and penetrate the surface, forming a durable bond between the steel and the glass enamel. The glass enamel layer serves to protect the tank core from corrosion during use.

- Non-enamel coated tank lining: Currently, most water heater manufacturers no longer produce this type of lining, as it causes rapid damage to the water heater.

2. Insulation layer

The heat-retaining foam layer is created from Polyurethane (PU), which is injected at high density into the gap between the plastic casing and the tank core of the water heater to retain heat and minimize heat loss while hot water is being heated in the tank, thereby helping to save electrical energy.

3. Water Heater Casing

The water heater casing is typically made of high-grade plastic for models with small storage capacity. Larger capacity models are additionally coated with a layer of electrostatic painted steel.

4. Heating Element

The main and most important part of the water heater is the heating element. The heating element of a water heater is usually made from an alloy or copper. The heating element must ensure good heat transfer, good electrical insulation, and a long service life.

5. Magnesium Anode

When in direct contact with water, the contact points can be corroded, leading to perforations, which can cause unpredictable and life-threatening consequences for the user. Therefore, the Magnesium Anode is a safety solution to protect the water heater tank core against electrochemical corrosion, increasing the lifespan of the water heater core.

So, how does the Magnesium Anode protect the water heater tank core? In short, the manufacturer temporarily introduces a chemical substance into the water heater that can react chemically with certain impurities in the water to prevent scaling on the heating rod and counteract chemical corrosion at the weld seams. For this reason, the Magnesium Anode must be replaced periodically after a period of use.

6. Temperature stabilizer and control unit – Thermostat (two functions)

- The first function is the control function (temperature stabilization): When the temperature inside the tank reaches 75ºC, the thermostat automatically cuts off the power supply to the heating element. Conversely, when the temperature drops, the thermostat automatically restores power to the heating element.

- The second function is the protective function: In case the first function malfunctions and fails to cut off power at 75ºC, the second function will activate and cut power to the entire system, ensuring safety for the user and the equipment. When the second function is activated, the water heater is operating abnormally and must be inspected before resetting the protective thermostat.

7. Power Cord

- The power cord is usually designed to be attached to an ELCB (earth leakage circuit breaker) anti-shock device. When a leakage current greater than or equal to 15mA occurs, the anti-shock device automatically cuts off power to the tank, thus ensuring the safety of the user and the equipment. (Older generation water heaters do not have this relay but have a location for installing an earth wire in the water heater’s electrical junction box).

- Note: ELCB is often mistakenly confused with the CB (circuit breaker) device, which is an automatic circuit breaker designed only to cut power in the event of an electrical short circuit. ELCB is an additional electrical safety device, used to detect leakage current running through a circuit, and in case of an incident, it automatically cuts off power based on the principle of differential current between the phase wire and the neutral wire.

8. Indicator Light

The indicator light has only one function: To let the user know whether the water heater is currently operating or not. The indicator light is usually integrated into the Thermostat unit.

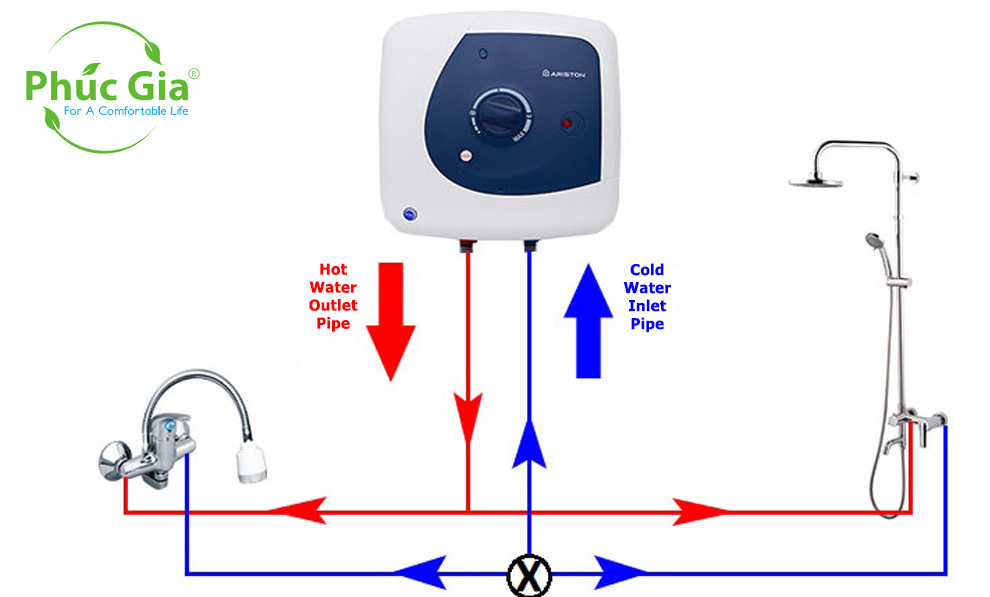

9. Water Inlet and Outlet

The water inlet and outlet are designed with large threads, making pipe connection easy and secure. The red color typically indicates the hot water outlet, usually positioned on the left side of the water heater. The blue color indicates the cold water inlet for the tank and is the port where the safety valve is installed, which controls the one-way supply of water to the tank.

10. One-way drain valve and Safety Valve (two functions)

- Safety function: Releases water when the tank encounters an unexpected pressure increase because, for some reason, the thermostat fails to automatically cut off power, leading to continuous power supply and a resulting pressure increase inside the tank due to boiling water turning into steam. In this case, the valve automatically relieves pressure to prevent the water heater from exploding.

- Operational function: Only allows water to enter the tank but prevents water from flowing in the reverse direction, even when the system’s water supply runs out. This keeps a fixed amount of water inside the tank sufficient to completely submerge the heating element, as the hot water outlet pipe is positioned higher than the heating element’s installation location.

II) Operating Principle of the Water Heater

- The operating principle of the water heater is similar to that of an electric kettle: it heats water using a high-power resistance wire (Heating Element) (1500W; 2500W, possibly up to 6000W). Although the water heater is designed more modernly than the electric kettle, the risk of electric shock to the user from both devices is the same.

- Many people believe that because the electric cutoff relay (Thermostat) is present, it is safe to leave the power plugged in 24/24 hours, even during use, unaware that this causes the heating element and other components—especially the insulation parts—to be damaged due to overload operation. Not to mention, this habit consumes a considerable amount of electricity for households and is a dangerous habit that needs to be eliminated when using a water heater.

- The phenomenon of electrical leakage in a water heater can still occur when there is a short circuit between the resistance wire (Heating Element) and the external environment. This becomes a reality when the insulating layer of the resistance wire is corroded or peels off during use, posing a danger to the user.

III) How to Resolve the Electrical Leakage Issue in Water Heaters

- Currently, to address this issue, some modern water heaters utilize a dual relay system consisting of two relays: The first is a thermal relay (No. 1), which is a capillary type (containing expanding gas sensitive to temperature) that measures the temperature from the center of the tank. It automatically turns the power supply ON/OFF according to a pre-set, adjustable mode, ensuring sufficient hot water and saving electrical energy. The second is a safety relay (No. 2), which automatically cuts off power if the thermal relay fails or the water overheats beyond the permissible limit.

- Apart from the cause related to the insulation material of the resistance wire (Heating Element), electrical leakage also occurs due to the “over-aging” of other components, including the rubber insulating gasket connecting the resistance wire, the tank shell, and the electric wires. The aging of this part creates cracks in the rubber material, leading to water seepage, which then conducts electricity to the outside. This crucial component can also be damaged and lose its sealing function, resulting in water leakage. When this occurs, the water wets the thermal relays, rendering the protection function ineffective.

- Another cause is the failure of the one-way valve, leading to the tank not containing water, but the resistance wire (Heating Element) continuing to operate.

- The final point that helps us save electricity costs is to avoid using the appliance during the peak hours of the electrical system. During these times, the source voltage often does not meet the manufacturer’s design requirements, leading to increased current consumption, low utilization efficiency, and a longer time needed to heat the water to the set temperature, resulting in wasted electricity payments. To overcome this problem, we can set up an automatic control device to supply power to the water heater before the peak hours in each residential area or according to the season of the year.

The above is Phuc Gia®’s analysis of the Components and Operating Principle of the Water Heater that we wish to share with organizations. In addition to providing information on the Components and Operating Principle of the Water Heater, Phuc Gia® is also a leading unit offering services such as Logistics Services, Certification and Declaration of Conformity Services, Energy Labeling Services, Food Safety Declaration Services, and especially Testing and Certification Services. Organizations in need should contact Phuc Gia® immediately to receive in-depth consultation and comprehensive Customs Clearance services in the fastest and most professional manner!

WHAT MAKES THE PHUC GIA® BRAND:

Phuc Gia® – The Leading Unit Providing Customs Services:

The reasons why all enterprises choose Phuc Gia® as the leading unit in consulting for Food Safety Conformity Declaration and Food Safety Regulatory Compliance Declaration, Energy Labeling, Conformity Certification, Cosmetic Declaration, and Logistics Services:

Phuc Gia® has over 10 years of experience in the industry, and is the first unit with sufficient capability to provide Customs services to over 500 large and small organizations In & Out of Vietnam, including: Sharp (2012); Samsung (2012); Hitachi (2013); Electrolux (2013); Panasonic (2013); LG (2013); Sony (2013); Siemens (2013); Mitsubishi (2013); GE (2013); Haier (2014); Toshiba (2014); Carrier (2014); Philips (2014); HappyCook (2015); General (2015); TCL (2015); Alaska (2015); Casper (2015); Gree (2016); Hải Hà (2016); VinMart (2017)…

Phuc Gia® owns a professional Consultation Team and workflow process, capable of answering all enterprise inquiries, helping customers optimize time, mental effort, physical effort, and minimize risks during the process of goods transportation and customs clearance procedures.

Phuc Gia® is the first & only unit to publicly announce the Global Listed Price on its Website and provide free one-year insurance to customers in the event that State legal regulations change!

FREQUENTLY ASKED QUESTIONS:

Despite our services being in the high-price segment, why is Phuc Gia® still chosen by enterprises as the leading reliable unit for customs services?

- This is a concern shared by many customers before choosing Phuc Gia® as their Customs Services provider.

- Over the past 10 years, Phuc Gia® has served over 500 large and small Domestic and International Enterprises. More than 90% of the enterprises that have used Phuc Gia®’s Customs Services agree that the quality of the Service is commensurate with the money they invest.

- Customers comment that: “The price the Enterprise pays when using Phuc Gia®’s Customs Services is SIGNIFICANTLY MORE COST-EFFECTIVE compared to the time and expense the Enterprise would incur to independently complete tasks such as: self-arranging product testing; self-researching and preparing dossiers; self-working with relevant ministries and departments to finalize dossiers; self-obtaining Customs Clearance permits…”

- Phuc Gia® commits to optimizing your time, mental effort, physical effort, and money during the Customs Clearance process, as well as MINIMIZING RISKS during the licensing process!

For more details, please contact us at:

PHUC GIA LABORATORY CORPORATION

PHUC GIA CERTIFICATION CENTER

PHUC GIA INSPECTION TESTING CENTER

Address: ICD Long Bien, No. 01 Huynh Tan Phat, Sai Dong B Industrial Park, Long Bien Ward, Hanoi City, Vietnam.

Hotline: 0981 996 996/ 0982 996 696/ 024 7779 6696

E-mail: lab@phucgia.com.vn

Website: phucgia.com.vn

Working time: Monday to Friday 8:00 – 18:30; Saturday 8:00 – 12:00

![QUOTATION – Testing and Other Certification Services [2025]](https://phucgia.com.vn/wp-content/uploads/2025/01/quotation.png)